Q-SUN XE-3 XENON TEST CHAMBER

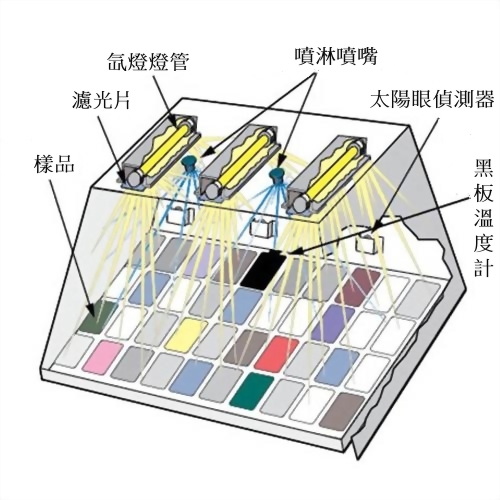

The Q-SUN Xe-3 tester is a full-featured lightfastness, colorfastness, and photostability chamber at a breakthrough price. It utilizes three separate xenon lamps for a large capacity. The Q-SUN Xe-3 tester’s slide out specimen tray is 451mm x 718mm and is useful for exposing large, three-dimensional parts or components. The Xe-3 tester offers standard humidity control, and optional spray, back spray and chiller features.

The Q-SUN Xe-3 is the only xenon arc tester that also has an optional dual spray capability. This allows for a second liquid such as acid rain or soap solutions, to be sprayed onto test specimens.

The Q-SUN Xe-3 is the simplest, most reliable, and easiest to use full-sized xenon arc chamber available.

A More Realistic Xenon

The Q-SUN Xe-3 tester’s xenon arc lamps provide the best match to the full spectrum of sunlight. Near-horizontal specimen mounting and optional water and back spray provide the most realistic moisture simulation available in a xenon arc tester. The Xe-3 tester also is the only xenon test chamber to offer a dual spray option, allowing a second liquid (such as acid rain) to be sprayed onto test specimens. An optional chiller for low temperature applications also allows for simultaneous control of both black panel and chamber air temperature.

Easy To Use

The Q-SUN Xe-3 xenon test chamber is easy to install (proper ventilation required). It is easy to use and practically maintenance-free. Specimen mounting and evaluation is fast and easy with the unique slide-out specimen tray. The Xe-3 tester is completely automated and can operate continuously, 24 hours per day, 7 days per week. Other features include:

- Remarkably simple user interface in five user-selectable languages: English, French, Spanish, Italian or German

- Built-in Ethernet connection for data logging

- Comprehensive self-diagnostic warnings and service reminders

- Quick and easy calibration with patented AUTOCAL system

Fast Results

Affordable

The Q-SUN Xe-3 tester’s low purchase price, low lamp prices and low operating costs create a breakthrough in the price/performance equation. Now even the smallest lab can afford xenon arc testing.

Models (see also Features Tab)

- Q-SUN Xe-3-H: full-spectrum sunlight with humidity control

- Q-SUN Xe-3-HS: full-spectrum sunlight with humidity control and spray

- Q-SUN Xe-3-HDS: full-spectrum sunlight with humidity control and dual spray

- Q-SUN Xe-3-HBS: full-spectrum sunlight with humidity control and water spray (front and back)

- Q-SUN Xe-3-HC: full-spectrum sunlight with humidity control and chiller

- Q-SUN Xe-3-HSC: full-spectrum sunlight with humidity control, spray and chiller

Optical Filters

Xenon light must be properly filtered to achieve the appropriate spectrum for each particular application. Differences in spectra may affect both the speed and the type of degradation. Three categories of filters are available to simulate a variety of service environments, shown below. The application or test method dictates which filters should be used.

Daylight Filters

Window Glass Filters

Window glass filters produce spectra equivalent to sunlight coming through window glass. This spectrum can also simulate other indoor lighting such as the harsh lighting found in a typical commercial or office environment. Window glass filters are used for indoor materials such as printing materials and textiles. Four different window glass filters are available for the Q-SUN Xe-3 tester: Window - Q, Window - B/SL, Window - SF-5 and Window - IR.

Extended UV Filters

The Q-SUN Xe-3 tester’s long-life filters are exceptionally durable and maintain the required spectrum indefinitely. After many years of use, Q-SUN filters have yet to show any signs of aging.

| Filter Name | Nominal Cut-On | Recommended Use |

| Daylight - Q | 295 nm | Best for correlation with outdoor exposures |

| Daylight - B/B | 290 nm | Best for correlation to some rotating-drum style testers |

| Daylight - F | 295 nm | Accurate match to the short-wave UV portion of sunlight Used in some ASTM and automotive test standards |

| Extended UV - Q/B | 275 nm | Used for some automotive test methods |

| Extended UV - Quartz | 250 nm | Very aggressive, very short-wave UV, extraterrestrial spectrum |

| Window - Q | 310 nm |

Sunlight North American window glass Meets most ISO & ASTM requirements for Window Glass Filters |

| Window - B/SL | 300 nm |

Recommended for AATCC procedures like TM 16-3 Meets most ISO & ASTM requirements for Window Glass Filters |

| Window - IR | 320 nm |

Reduced heat for lower exposure temperatures Recommended for ISO 105 B02 “European Conditions” Does not meet the requirements for most ISO & ASTM Window Glass Filters |

| Window - SF5 | 325 nm | Used for some automotive interior tests (e.g. Ford) |

| Xe-1 | Xe-2 | Xe-3 | Irradiance (W/m2 ) | |||

| @340 nm | @420 nm | @TUV | ||||

| Daylight - Q | ● | ● | ● | 0.25 ~ 0.68 | 0.45 ~1.50 | 20 ~ 75 |

| Daylight - B/B | ● | ● | ● | 0.25 ~ 0.68 | ||

| Daylight - F | ● | ● | ● | 0.25 ~ 0.80 | ||

| Extended UV - Quartz | ● | --- | ● | 0.25 ~ 0.68 | ||

| Extended UV - Q/B | ● | ● | ● | 0.25 ~ 0.68 | ||

| Window - Q | ● | ● | ● | 0.25 ~ 0.55 | 20 ~ 70 | |

| Window - B/SL | ● | ● | ● | 0.25 ~ 0.55 | ||

| Window - SF5 | ● | ● | ● | --- | ||

| Window - IR | ● | ● | ● | --- | 20 ~ 42 | |

| Window - B04 | --- | ● | --- | --- | ||

| Models |

Xe-3-H Xe-3-HS Xe-3-HDS Xe-3-HBS |

Xe-3-HC Xe-3-HSC |

||||

|

Black Panel Temp (°C) Light Cycle Light Cycle w/IR Filter Dark Cycle Light+Immersion Cycle Dark+Immersion Cycle |

BP 45 - 110 40 - 90 25 - 50 ----- ----- |

IBP 50 - 120 45 - 100 25 - 50 ----- ----- |

BP 35 - 110 30 - 90 15 - 50 ----- ----- |

IBP 36 - 120 31 - 100 15 - 50 ----- ----- |

||

|

Chamber Air Temp (°C) Light Cycle (any filter) Dark Cycle |

35 - 65 25 - 50 |

25 - 65 15 - 50 |

||||

| Relative Humidity | 95% - 20% | |||||

| Specimen Area | 45×72 cm (d×w) (17.8×28.3 in) | |||||

|

Specimen Capacity5 (qty @ size) |

55 @ 51×102 mm (2×4 in) | |||||

|

Total Specimen Weight (distributed evenly) |

23 kg (50 lbs) max | |||||

| Inlet Water Pressure and Purity |

H/HC Models: 0.7-6.2 bar (10-90 psi); > 200 kΩ∙cm; < 5 μS/cm; < 2.5 ppm TDS S/SC/W/HS/HDS/HBS/HSC Models: 2.1-6.2 bar (30-90 psi); > 5 MΩ∙cm; < 0.2 μS /cm; < 0.1 ppm TDS; < 0.1 ppm colloidal silica |

|||||

| Water Consumed with Spray On |

0.16 L/min (front) 0.4 L/min (front & back) |

0.16 L/min | ||||

|

Water Consumed with Humidifer On |

44 L/day | |||||

|

External Dimensions8 (w × h × d) |

91×178×99 cm (36×70×39 in) |

78×94×94 cm (31×37×37 in) Chiller Only |

||||

| Weight |

190-233 kg (420-512 lbs) |

85 kg (186 lbs) Chiller Only |

||||

| Electrical Requiremts |

208/230V ± 10% 3-Ф, 50/60 Hz, 39A |

208/230V ± 10% 3-Ф, 50/60 Hz, 44A; or |

||||

|

400V ± 10% 3-Ф, 50/60 Hz, 26A |

400V ± 10% 3-Ф, 50/60 Hz, 26A |

|||||